Types of plexiglass

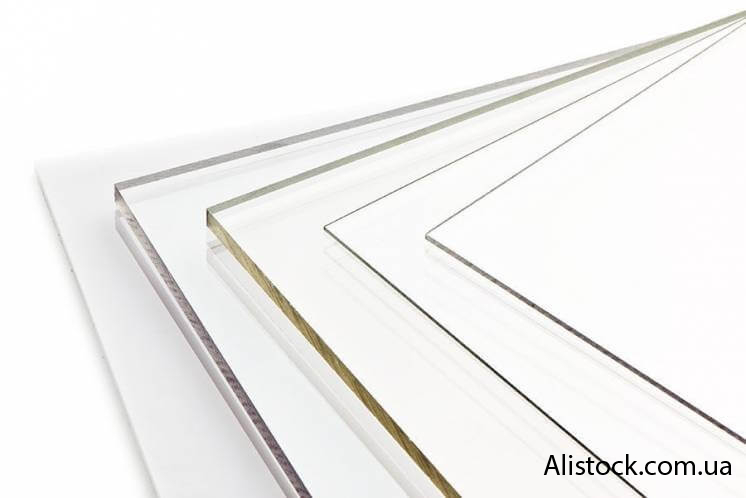

- organic glass is transparent, perfectly smooth on each side, transmitting 92% of light;

- transparent colored, coated with paint;

- transparent corrugated: as a rule, one surface is smooth, and a three-dimensional pattern is applied to the other;

- white matte, with light transmission from 20 to 70%;

- colored frosted glass;

- corrugated matte: on one side there is a smooth surface, on the other there is a pattern.

The choice of option depends on the goals pursued and the area of use of the material. Transparent glass is most often used in medicine, construction, frosted corrugated glass - in design, etc.

Application

Plexiglas is used to produce stands, display cases and other elements of commercial equipment. In lighting technology, it is suitable for the production of diffusers, partitions, lampshades, front screens, etc. Front glass for illuminated letters, boxes and other elements of outdoor advertising are also made of plexiglass. The material of increased thickness is suitable for glazing of boats and aircraft. In instrument making, cases, dials, various containers, dielectric parts, etc. are made from it.

Special attention should be paid to medicine. Organic glass has excellent contact with the tissues of the human body. Due to this, it is used for the production of hard intraocular and contact lenses, as well as in the production of glasses. This material is also widespread in dentistry, in the manufacture of orthodontic devices and prostheses.

Comparison of plexiglass with similar materials

In appearance and properties, plexiglass can be compared with ordinary glass, as well as with transparent plastics. In both cases, it will be a winner. It is 2.5 times lighter than regular glass, but 10 times stronger. When broken, it does not fall into fragments, so it is completely safe. In construction, it is valued for its good sound and heat insulating properties (2 mm plexiglass can be compared with 10 mm regular glass). In terms of light transmission, this material is second only to quartz glass. Unlike ordinary glass, its processing does not require much effort. It can be bent radially, without preheating, or molded. All this significantly expands the scope of its use.

Compared to plastics, which require additional protection, organic glass is the most resistant to ultraviolet radiation. It is 17% lighter than compact PVC and 15% heavier than polystyrene. Moreover, the first can only be used at temperatures up to +60°C, the second - up to +70°C, and acrylic glass can easily withstand from -40°C to +80-90°C. In terms of temperature resistance, it can only be compared with polycarbonate. This material can withstand temperatures from -50°C to +120°C.

Acrylic glass does not contain toxic substances and is completely safe for humans and the environment. It is used on the streets and in buildings, also in children's institutions, hospitals, and sanatoriums.

Types of plexiglass

- organic glass is transparent, perfectly smooth on each side, transmitting 92% of light;

- transparent colored, coated with paint;

- transparent corrugated: as a rule, one surface is smooth, and a three-dimensional pattern is applied to the other;

- white matte, with light transmission from 20 to 70%;

- colored frosted glass;

- corrugated matte: on one side there is a smooth surface, on the other there is a pattern.

The choice of option depends on the goals pursued and the area of use of the material. Transparent glass is most often used in medicine, construction, frosted corrugated glass - in design, etc.

Application

Plexiglas is used to produce stands, display cases and other elements of commercial equipment. In lighting technology, it is suitable for the production of diffusers, partitions, lampshades, front screens, etc. Front glass for illuminated letters, boxes and other elements of outdoor advertising are also made of plexiglass. The material of increased thickness is suitable for glazing of boats and aircraft. In instrument making, cases, dials, various containers, dielectric parts, etc. are made from it.

Special attention should be paid to medicine. Organic glass has excellent contact with the tissues of the human body. Due to this, it is used for the production of hard intraocular and contact lenses, as well as in the production of glasses. This material is also widespread in dentistry, in the manufacture of orthodontic devices and prostheses.

Comparison of plexiglass with similar materials

In appearance and properties, plexiglass can be compared with ordinary glass, as well as with transparent plastics. In both cases, it will be a winner. It is 2.5 times lighter than regular glass, but 10 times stronger. When broken, it does not fall into fragments, so it is completely safe. In construction, it is valued for its good sound and heat insulating properties (2 mm plexiglass can be compared with 10 mm regular glass). In terms of light transmission, this material is second only to quartz glass. Unlike ordinary glass, its processing does not require much effort. It can be bent radially, without preheating, or molded. All this significantly expands the scope of its use.

Compared to plastics, which require additional protection, organic glass is the most resistant to ultraviolet radiation. It is 17% lighter than compact PVC and 15% heavier than polystyrene. Moreover, the first can only be used at temperatures up to +60°C, the second - up to +70°C, and acrylic glass can easily withstand from -40°C to +80-90°C. In terms of temperature resistance, it can only be compared with polycarbonate. This material can withstand temperatures from -50°C to +120°C.

Acrylic glass does not contain toxic substances and is completely safe for humans and the environment. It is used on the streets and in buildings, also in children's institutions, hospitals, and sanatoriums.

You can buy plexiglass in our store by placing an order online 24/7 or by calling the hotline

: